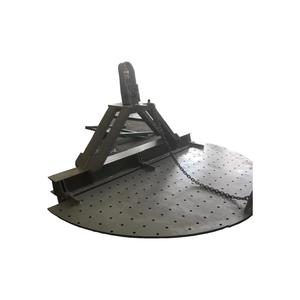

i-aluminiyam yokunyibilikisa iziko lokungeniswa kumatshini wokutyhilwa kwentsimbi ye-automation ye-automation yase-china yemveliso yombaneIziko lokungeniswaI-furnace induction ene-frequency range ye-150 ukuya kwi-10000 Hz ibizwa ngokuba yi-intermediate frequency induction furnace. I-furnace ye-medium frequency induction sisixhobo esikhethekileyo sokunyibilikisa esifanelekileyo sokunyibilikisa isinyithi esikumgangatho ophezulu kunye neealloys. Ineengenelo ezinje ngesantya sokunyibilika okukhawulezayo, ukusebenza kakuhle kwemveliso, ukuguquguquka okuqinileyo, ukusetyenziswa okuguquguqukayo, isiphumo esihle sokuvuselela i-electromagnetic, ukusebenza ngokulula kokuqalisa, kunye nolwelo lwentsimbi olugqunywe yi-slag (ukunciphisa ungcoliseko lomoya wolwelo lwentsimbi). Isixhobo esipheleleyo se-medium frequency induction furnace ibandakanya: unikezelo lwamandla kunye nenxalenye yolawulo lombane, indawo yomzimba wesithando somlilo, isixhobo sokuhambisa, kunye nenkqubo yokupholisa amanzi.I-furnace ye-frequency induction i-medium frequency ifanelekile ngokukodwa kwiziko ezinkulu, eziphakathi, kunye nezincinci ezinomthamo wamashumi eetoni ze-10kg. Isetyenziselwa ukunyibilikisa intsimbi, isinyithi, ubhedu, i-aluminiyam, kunye nezinye iintsimbi ezingezizo i-ferrous kunye ne-alloys yazo, kunye nokugquma kwesinyithi. Inokulungelelaniswa okunamandla kwizinto zomlilo kwaye ifanelekile kwimisebenzi ephakathi. Ulwakhiwo lwesithando somlilo kunye nokusetyenziswa ziyafana nezo zesithando somlilo esingenaziko. Ukusukela ngeminyaka yoo-1970s, ngamandla andayo kunye nokuthembeka kobuchule obuphezulu, obungaguqukiyo, kunye nesinyithi songa i-thyristor phakathi konikezelo lwamandla ombane ophakathi, amafurnashi aphakathi aphuhliswe ngokukhawuleza ngaphakathi nangaphandle. Abanamalungelo acacileyo kuphela kumthamo omncinci kunye nobukhulu obuphakathi, kodwa kwakhona bathatha indawo yamaziko okwenziwa kwemizi-mveliso angenantliziyo kumthamo omkhulu.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy